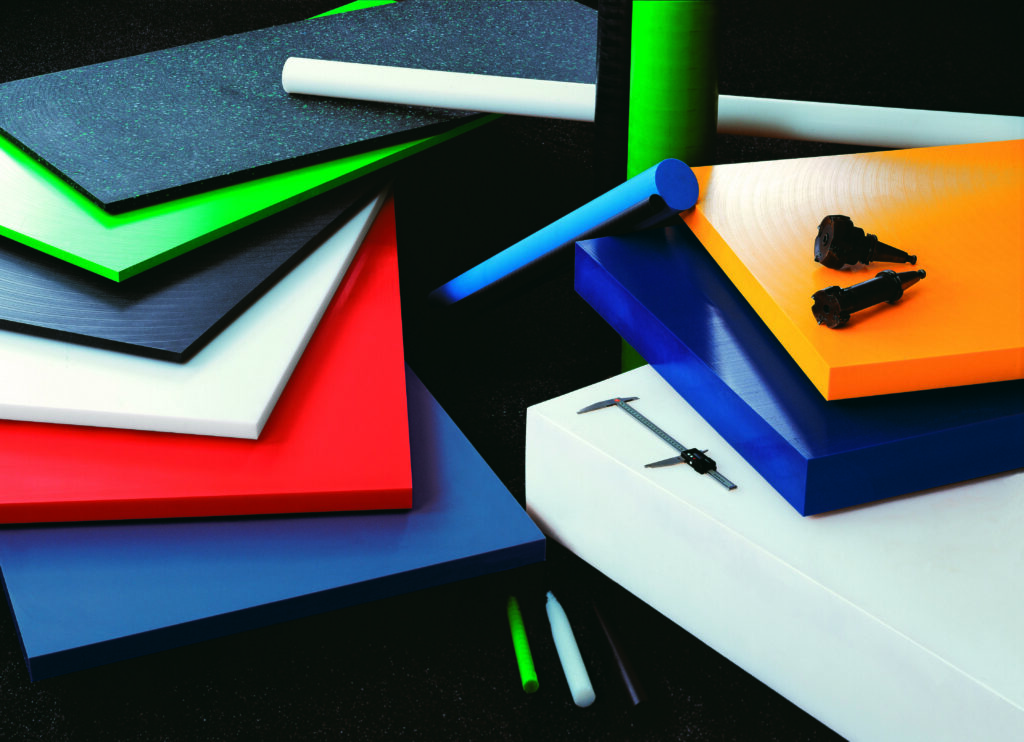

POLIETILENE

Le nostre presse con una lunghezza massima di 10.200 mm (larghezza massima di 1.250 mm), una larghezza massima di 2.500 mm (lunghezza massima 6.100 millimetri) e uno spessore pressato di oltre 200 mm e garantiscono la fornitura di quasi tutti i più comuni prodotti semilavorati necessario.

Il nostro magazzino di lastre copre circa 2.000 mq e contiene sia prodotti standard e molte qualità speciali e colori. I formati standard, che dipendono dalla qualità del materiale, sono elencate ai punti di menu separati.

| Dimensions | Thickness | Tolerance |

| 1.010 x 2.020 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.010 x 3.030 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.010 x 4.020 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.010 x 6.140 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.220 x 2.020 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.220 x 2.500 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.260 x 3.030 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.260 x 10.200 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 2.020 x 4.020 mm | 10 – 200 mm | ± 0,2/0,3 mm |

| 2.020 x 6.050 mm | 10 – 200 mm | ± 0,2/0,3 mm |

| 2.520 x 6.050 mm | 10 – 170 mm | unplaned |

| Dimensions | Thickness | Tolerance |

| 2.000 x 1.000 mm | 1 | -0 / +0,4 mm |

| 2.000 x 1.000 mm | 2 | ± 0,2 mm |

| 2.000 x 1.000 mm | 3 | ± 0,2 mm |

| 2.000 x 1.000 mm | >4 | ± 0,2 mm |

| 2.000 x 1.000 mm | 5 | ± 0,2 mm |

| 2.000 x 1.000 mm | 6 | 0,3 mm |

| 2.000 x 1.000 mm | 8 | ± 0,3 mm |

BY WAY OF SPECIALLY SELECTED ADDITIVES THE MATERIAL WEFAPRESS ST 1000® CAN BE ENHANCED TO CATER TO SPECIFIC DEMANDS. THIS IS PRIMARILY ACCOMPLISHED BY THE USE OF LUBRICANTS AND BIODEGRADABLE OILS.

| Dimensions | Thickness | Tolerance |

| 1.010 x 2.020 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.010 x 3.030 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.010 x 4.020 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.010 x 6.140 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.220 x 2.020 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.220 x 2.500 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.260 x 3.030 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.260 x 10.200 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 2.020 x 4.020 mm | 10 – 200 mm | ± 0,2/0,3 mm |

| 2.020 x 6.050 mm | 10 – 200 mm | ± 0,2/0,3 mm |

| 2.520 x 6.050 mm | 10 – 170 mm | Unplaned |

Availability:

- Standard thicknesses available from the warehouse

| Dimensions | Thickness | Tolerance |

| 1.010 x 2.020 mm | 10 – 150 mm | +0,2 / +0,6 mm |

| 1.010 x 3.030 mm | 10 – 150 mm | +0,2 / +0,6 mm |

| 1.010 x 4.020 mm | 10 – 150 mm | +0,2 / +0,6 mm |

| 1.010 x 6.140 mm | 10 – 150 mm | +0,2 / +0,6 mm |

| 1.220 x 2.020 mm | 10 – 180 mm | +0,2 / +0,6 mm |

| 1.220 x 2.500 mm | 10 – 180 mm | +0,2 / +0,6 mm |

| 1.260 x 3.030 mm | 10 – 180 mm | +0,2 / +0,6 mm |

| 1.260 x 10.200 mm | 10 – 180 mm | +0,2 / +0,6 mm |

| 2.020 x 4.020 mm | 10 – 150 mm | ± 0,2/0,3 mm |

| 2.020 x 6.050 mm | 10 – 150 mm | ± 0,2/0,3 mm |

| 2.520 x 6.050 mm | 10 – 170 mm | unplaned |

Availability:

- Standard thicknesses available from the warehouse

| Dimensions | Thickness | Tolerance |

| 1.010 x 2.020 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.010 x 3.030 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.010 x 4.020 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.010 x 6.140 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.220 x 2.020 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.220 x 2.500 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.260 x 3.030 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 1.260 x 10.200 mm | 10 – 200 mm | +0,2 / +0,6 mm |

| 2.020 x 4.020 mm | 10 – 200 mm | ± 0,2/0,3 mm |

| 2.020 x 6.050 mm | 10 – 200 mm | ± 0,2/0,3 mm |

| 2.520 x 6.050 mm | 10 – 170 mm | unplaned |

| Material | ||

| St 1000 | St 500 | A4 |

| Max. lenght | Max. width | Max. thickness |

| 1.300 mm | 1.200 mm | 650 mm |

| 1.220 mm | 500 mm | 490 mm |

Other dimensions upon request.

| Dimensions | Thickness | Tolerance |

| 1.010 x 2.020 mm | 10 – 80 mm | ± 0,2/0,3 mm |

| 1.010 x 3.030 mm | 10 – 80 mm | ± 0,2/0,3 mm |

| 1.220 x 2.020 mm | 10 – 80 mm | ± 0,2/0,3 mm |

| 1.220 x 2.050 mm | 10 – 80 mm | ± 0,2/0,3 mm |

| 4.040 x 2.020 mm | 10 – 80 mm | ± 0,2/0,3 mm |

| 6.050 x 2.020 mm | 10 – 80 mm | ± 0,2/0,3 mm |

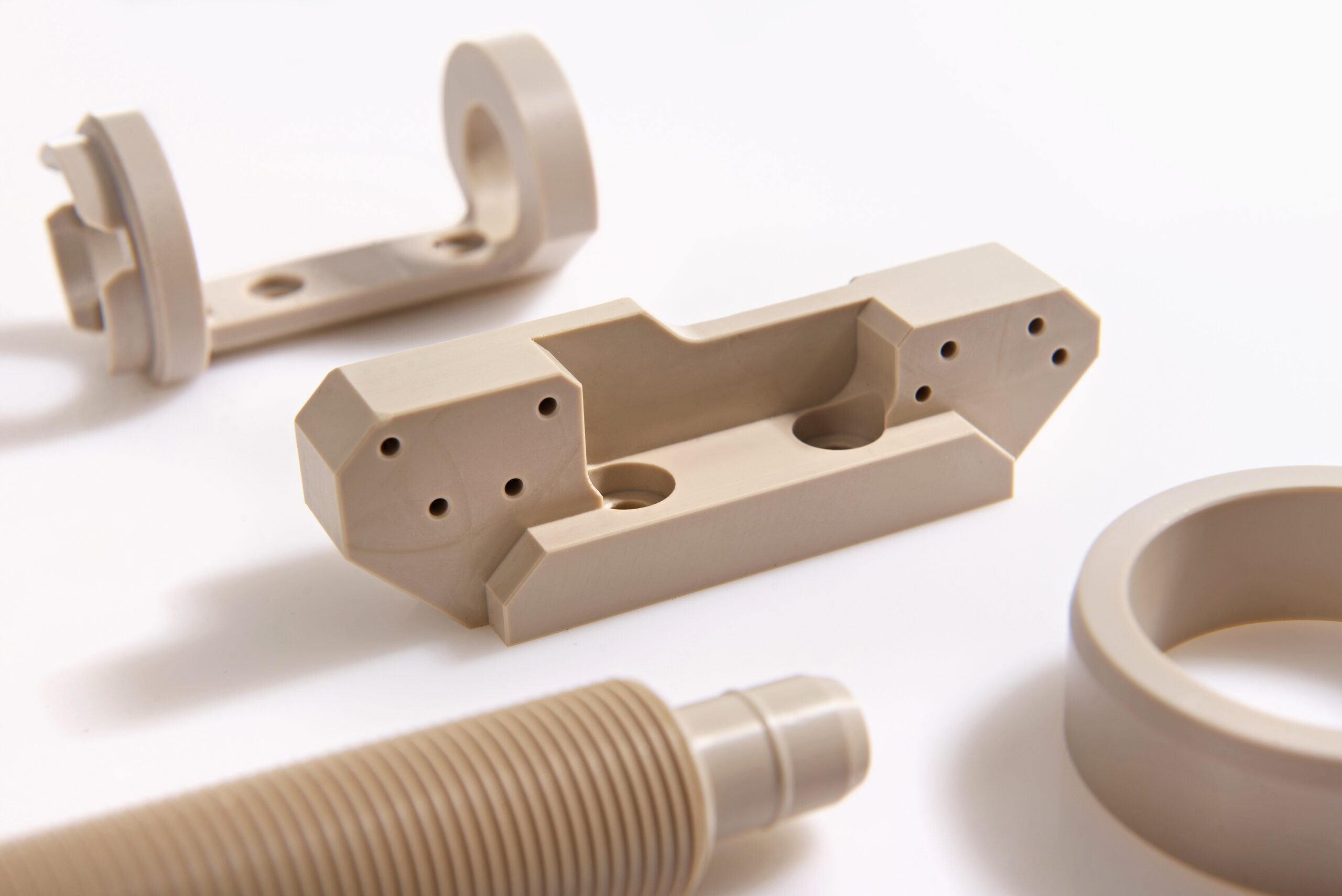

TECNOPOLIMERI

Oltre alle comprovate qualità nei materiali standard e premium in Polietilene, Wikiplast fornisce tutta la gamma di tecnopolimeri.

| The characteristic property profile of POM: | |||

| Low moisture absorption | High mechanical strength and rigidity | Very good tensibility | Good sliding properties |

| Standard color(s): | Delivery form | Application areas |

| Natural, Black | Sheets, Rods | Bearings and gearwheels Isulating parts Precision parts for the mechanical engineering |

| Special color(s): | Finished parts: | |

| — | Upon request |

Wefapress POM

POM is a polyacetal. This material features very good mechanical characteristics, but offers less wear resistance than Pa 6 G.

| The characteristic property profile of PETP: | ||||

| Good hardness, rigidity and strength | Excellent sliding characteristics | Low sliding abrasion | Very good dimensional stability | Very low moisture absorption |

| Standard color(s): | Delivery form | Application areas |

| Natural | Sheets, Rods | Mechanical engineering Gearwheels Frame- and pump components Cam discs Sliding elements |

| Special color(s): | Finished parts: | |

| — | Upon request |

Wefapress PETP

PETP is a semi-crystalline thermoplastic polyethylene terephthalate. This material features wear levels that are better than those of POM and also less moisture absorption than POM.PETP is especially suitable for complex precision parts.

| The characteristic property profile of PETP: | ||||

| Good hardness, rigidity and strength | Excellent sliding characteristics | Low sliding abrasion | Very good dimensional stability | Very low moisture absorption |

| Standard color(s): | Delivery form | Application areas |

| Light grey | Sheets, Rods | Mechanical engineering Gearwheels Frame- and pump components Cam discs Sliding elements |

| Special color(s): | Finished parts: | |

| — | Upon request |

Wefapress PETP-SP

PETP-SP is a polyethylene terephthalate modified with special homogenously distributed solid lubricants. This composition leads to “self-lubrication” of the material, which further improves the sliding properties and wear resistance of the material compared to pure PETP. This specialty promotes greater carrying capacity and also prevents the slip-stick effect.

| The characteristic property profile of PA 6: |

| High impact strength |

| Standard color(s): | Delivery form | Application areas |

| Natural, Black | Sheets, Rods | Components exposed to shock and impact Gearwheels Light-duty slide bearings Chain guides |

| Special color(s): | Finished parts: | |

| — | Upon request |

Wefapress PA 6

PA 6 is a polyamide that is manufactured in an extrusion process. The moisture absorption is relatively high compared to PA 6 G, and the wear resistance and dimensional stability are at lower levels than those found in PA 6 G.

| The characteristic property profile of PA 6.6: | |

| High level of hardness | Very good wear resistance |

| Standard color(s): | Delivery form | Application areas |

| Natural | Sheets, Rods | Friction bearing Friction sheets |

| Special color(s): | Finished parts: | |

| — | Upon request |

Wefapress PA 6.6

Like PA 6, PA 6.6 is a polyamide that is also manufactured in an extrusion process. It does, however, exhibit greater strength, hardness and wear resistance than PA 6. The mechanical characteristics are similar to those of PA 6G.

| The characteristic property profile of PA 6 G: | ||

| Good abrasion and wear resistance | High tensile and compressive strength levels | Good dimensional stability |

| Standard color(s): | Delivery form | Application areas |

| Natural, Black | Sheets, Rods | Cam- and guide rollers Rope rollers Gearwheels Slide bearings Chain guides |

| Special color(s): | Finished parts: | |

| — | Upon request |

Wefapress PA 6 G

PA 6 G is a cast polyamide that is manufactured by direct polymerization. It is available in practically unlimitedly large dimensions, and its mechanical characteristics are superior to those found in extruded polyamides.

| The characteristic property profile of PA 6 G + Oil: | |

| Excellent wear resistance | Low coefficient of friction during dry running |

| Standard color(s): | Delivery form | Application areas |

| Black, Yellow | Sheets, Rods | Chain guides and guide rollers Bearings Deflection rollers Guide rails Conveying screws Conveying stars |

| Special color(s): | Finished parts: | |

| — | Upon request |

Wefapress PA 6 G + Oil

PA 6 G + Oil is a cast polyamide that is manufactured by direct polymerization. PA 6 G + Oil is PA 6 G modified by means of integrated lubrication with oil, solid lubricants and stabilizers. This produces a coefficient of friction that is up to 50% lower, as well as wear resistance up to five times greater than other polyamides offer.

| The characteristic property profile of PA 12 G: | |||

| Low density | Low moisture absorption | ||

| Standard color(s): | Delivery form | Application areas |

| Natural | Sheets, Rods | Gearwheels Pinions Crane supports |

| Special color(s): | Finished parts: | |

| — | Upon request |

Wefapress PA 12 G

PA 12 G is a cast polyamide that is cast from laurin lactam without pressure. It features lower moisture absorption than the material PA 6 G.

| The characteristic property profile of PA 4.6: | ||

| High level of thermal stability | Good wear resistance | High level of rigidity |

| Standard color(s): | Delivery form | Application areas |

| Red-brown | Sheets, Rods | Conveyor systems |

| Special color(s): | Finished parts: | |

| — | Upon request |

Wefapress PA 4.6

PA 4.6 is a polyamide manufactured by extrusion. The material can be subjected to higher temperature ranges than, for example, PA 6 or PA 6.6.

| The characteristic property profile of PEEK: | |||

| Highly dimensionally stable | Good shape retention in heat | Highly resistant to chemicals | Flame retardant |

| Standard color(s): | Delivery form | Application areas |

| Natural | Sheets, Rods | Transport technology Aircraft and aerospace industries Shock absorbers Valve linigs Seals |

| Special color(s): | Finished parts: | |

| — | Upon request |

Wefapress PEEK

PEEK is a semi-crystalline thermoplast. The optimal combination of mechanical characteristics distinguish this material as an engineering plastic. Thanks to its good resistance to various fluids, the material is physiologically harmless. PEEK produces the least smoke of any thermoplast.

| The characteristic property profile of PEEK GL: | |||

| Highly dimensionally stable | Good shape retention in heat | Highly resistant to chemicals | Flame retardant |

| Standard color(s): | Delivery form | Application areas |

| Black | Sheets, Rods | Automation technology Friction bearings |

| Special color(s): | Finished parts: | |

| — | Upon request |

Wefapress PEEK GL

PEEK GL is a semi-crystalline thermoplast with selectively improved sliding properties achieved by the addition of solid lubricants. The optimal proportion of mechanical characteristics distinguish this material as an engineering plastic. Thanks to its good resistance to various fluids, the material is physiologically harmless. PEEK GL produces the least smoke of any thermoplast.

| The characteristic property profile of TORimid: | ||

| High temperature stability | Excellent wear characteristics | Good UV resistance |

| Standard color(s): | Delivery form | Application areas |

| Black | Sheets | Sliding elements Rotors Pump parts |

| Special color(s): | Finished parts: | |

| — | Upon request |

Wefapress TORimid (PAI)

The engineering plastic TORimid (PAI) is ideal for applications in the high temperature range thanks to its excellent mechanical performance and the high level of dimensional stability. The plastic is also outstandingly suitable for precision parts for high-tech devices.

| The characteristic property profile of PTFE: | ||

| Excellent chemical resistance | Low friction coefficient | Good temperature stability |

| Standard color(s): | Delivery form | Application areas |

| Natural | Sheets, Rods | Seals Guides Light-duty machine part |

| Special color(s): | Finished parts: | |

| — | Upon request |

Wefapress PTFE

The engineering plastic PTFE (polytetrafluoroethylene) is a semi-crystalline polymer made of fluorine and carbon. Thanks to its resistance to chemicals and its temperature stability, it is excellently suitable for areas in which products are transported, dried or cooled.

| The characteristic property profile of PVC: | |||

| High impact strength | Excellent chemical resistance | Flame retardant | Good machining possibilities |

| Standard color(s): | Delivery form | Application areas |

| Grey, Black, Red | Sheets, Rods | Covering Chemical machines Container construction Suitable for field work |

| Special color(s): | Finished parts: | |

| — | Upon request |

Wefapress PVC

PVC is a polyvinyl chloride and is one of the thermoplastic plastics. PVC not only has excellent resistance to chemicals, it is also classified as flame retardant at the highest level without the use of any additives.

| The characteristic property profile of PVDF: | |

| Good mechanical, thermal and electrical characteristics | Excellent chemical resistance |

| Standard color(s): | Delivery form | Application areas |

| Natural | Sheets, Rods | Chemical industry Food industry |

| Special color(s): | Finished parts: | |

| — | Upon request |

Wefapress PVDF

PVDF is an unreinforced, highly crystalline fluoropolymer. This material offers better dimensional stability and better wear levels than PTFE.

BARRE

Tondi in PEUHMW naturale verde e nero estrusi, con diametro da 20 a 250 mm e 2000 mm di lunghezza.

COLOR CARD

Many different shades are available for you to choose from.

Simply take a look at our color card.

SEMILAVORATI

Il pioniere nel campo della lavorazione PE

Come primo produttore al mondo di lastre in polietilene, manteniamo uno stretto ed eccellente contatto con i fornitori di materie prime e costruttori di macchine. Approfittate della nostra eccezionale conoscenza delle materie prime e delle capacità di produzione superiore alla norma. I nostri processi produttivi ottimizzati e il know-how dei nostri dipendenti altamente qualificati sono la garanzia di prodotti di qualità superiore. In aggiunta alla nostra gamma di lastre standard, speciali e tondi, siamo in grado di supportarvi al fine di trovare le soluzioni per progetti speciali.

Punti di forza dei nostri prodotti semilavorati

- Decenni di esperienza (dal 1953) nella produzione lastre

pressate / bassa tensione semilavorati in PE-UHMW (e

materiale rigenerato), PE-HMW e PP a magazzino - Ampio programma premium (circa 20 tipi di PE)

- Lunghezza lastre fino ad un massimo di 10250 millimetri,

larghezza fino ad un massimo 2.560 millimetri e spessori fino a 200

mm (230 mm) - Ampia scelta di colori: 40 colori standard, altri colori a progetto

- Cross-linking e stabilizzazione UV

- Blocchi in PE pressato fino a spessori di 650 mm

- La più recente tecnologia di saldatura e relative attrezzature

Sistemi di Modern Temper - Capacità di piallatura orbitale fino a larg. 1330 mm

(ROTOPLAST), piallatura lineare fino a 2050 mm (REX) - Esame ecografico sui prodotti

- Tondi in PE realizzati accuratamente partendo da lastre

pressate PE-UHMW - Partner Ticona dal 1955

Le nostre presse, ci permettono di avere diversi formati lastra. Pressiamo fino a spessore 200 mm.

Abbiamo una grande disponibilità di semilavorati a magazzino.

STANDARD QUALITIES

We deliver all of the materials mentioned here as semi-finished or finished parts. We are specialized in manufacturing customer-specific orders according to drawings, samples, or 3D models.

The information provided on the following pages represents our knowledge as of today. No agreement or guarantee regarding specific characteristics can be derived from the information contained in the datasheets. Users are responsible for deciding on the suitability of a material for a specific purpose. The data supplied are subject to change.

PREMIUM QUALITIES

Using specially selected additives, the material Wefapress St 1000® can be enhanced to cater to the respective, specific demands. This is primarily accomplished by way of additives and biodegradable oils.

The following shows you a brief overview of our materials, each with the respective properties and application areas.